Create or update your garden with 25% off the Retail price of ALL our quality containerised trees! This offer is valid until 30th April 2026. Use code ALLtrees25 at checkout, or CONTACT US directly to order.

During the months of May to July, our early cold morning starts result in bareroot trees dug for the days grading.

Using minimal people, trees are lifted with minimal disturbance to the soil. Each year we are improving working efficiencies with introduced technology making a difficult, labour-intensive job easier and quicker.

The seeded interrow is used for biodiversity reasons as it helps reduce compaction holds the soil and nutrient in place during in rain and wind events while at the same time allowing organic matter to break down into the soil.

A close up of the digging mechanism. Trees are undercut, gently lifted and soil is removed. The trees move up a belt system where they are then collected and piled on speciality made stillages. The digging machinery we use ensures minimal damage to root systems, branches or soil.

A close-up of the collection process off the converyor belt, where trees are collected and placed on the stillage. Note that all the soil is removed and left in the paddock for reuse.

Our process achieves minimal disturbance to the soil so paddocks are ready swiftly ready for rejuvenation and reuse. Trees in remaining rows are free-standing, tall and uniform ready for harvest.

It is a straight forward process to lift trees during the winter. Extra care is taken to lift the trees from the ground so that they are in perfect condition for the next stage of their journey. Minimal handling reduces stress and increases resilience.

Trees are grown to a standard note the calliper and the branch structure. Tree identification tags are on the first and last tree in a batch to ensure no product mix ups.

Once collected, trees are graded. Our staff tie material into easy to handle bundles of 5 or 10. They record the consistency of the batch and size of the calliper and quality of their root systems.

Each tree is examined for quality, size and health, such as these Liriodendron tulipifera. Only the best trees are delivered to the customers.

Trees have been graded and bundled into groups of 5 or 10. They are then placed onto pallets and tied down securely to eliminate excessive handling. Keeping the trees moist wile delivering provides a perfect tree for the next stage of its journey. The easier they are to handle the less stress results and the better the outcome.

Orders are transferred directly onto the pallets and then tied down securely. Less manual handling at this stage reduces the stress level of the trees.

When the complete order is assembled, bundles and palletised trees are then delivered to the customer as quickly as possible.

Receive all the latest news, product information, collections, projects, tips and special offers straight to your inbox each month or so.

Receive all the latest news, product information, collections, projects, tips and special offers straight to your inbox each month or so.

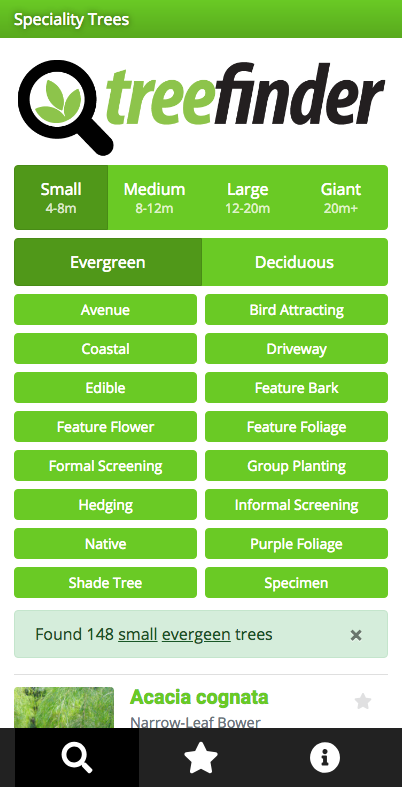

Treefinder can help you identify the perfect tree for your next project!

With over 400 tree varieties for review, the Treefinder app enables you to conveniently browse and compile a list of trees suitable for a number of common landscaping uses - from attracting birds to creating a formal screen or hedge. By selecting desired size, foliage, and a few categories, Treefinder opens up a world of possibilities.

Once you've found the perfect tree you can click through to our website for more information, availability and a quote.

We are specialists in the environmentally sustainable production of premium quality advanced landscaping trees and screens.

For more than 49 years Speciality Trees has been a leader in the production and supply of advanced environmentally sustainable, containerised landscape trees for local government, the landscaping industry and retailers.

Learn more